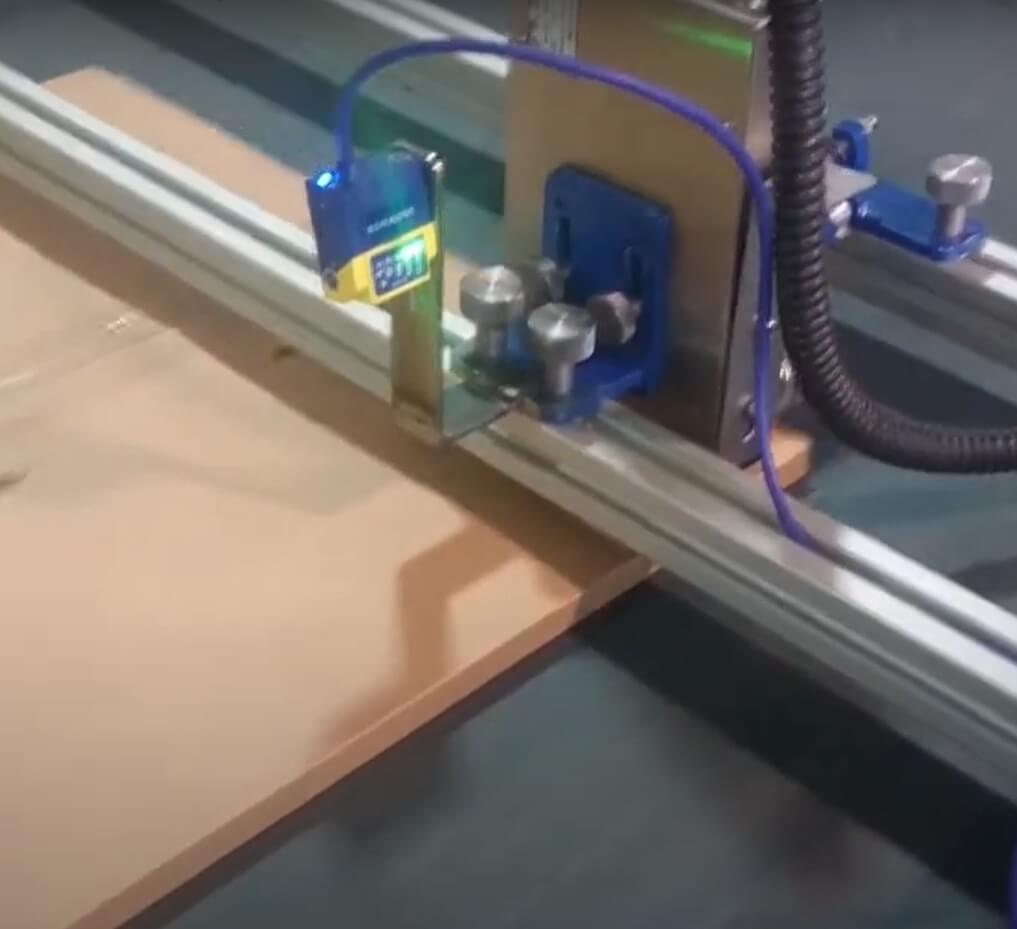

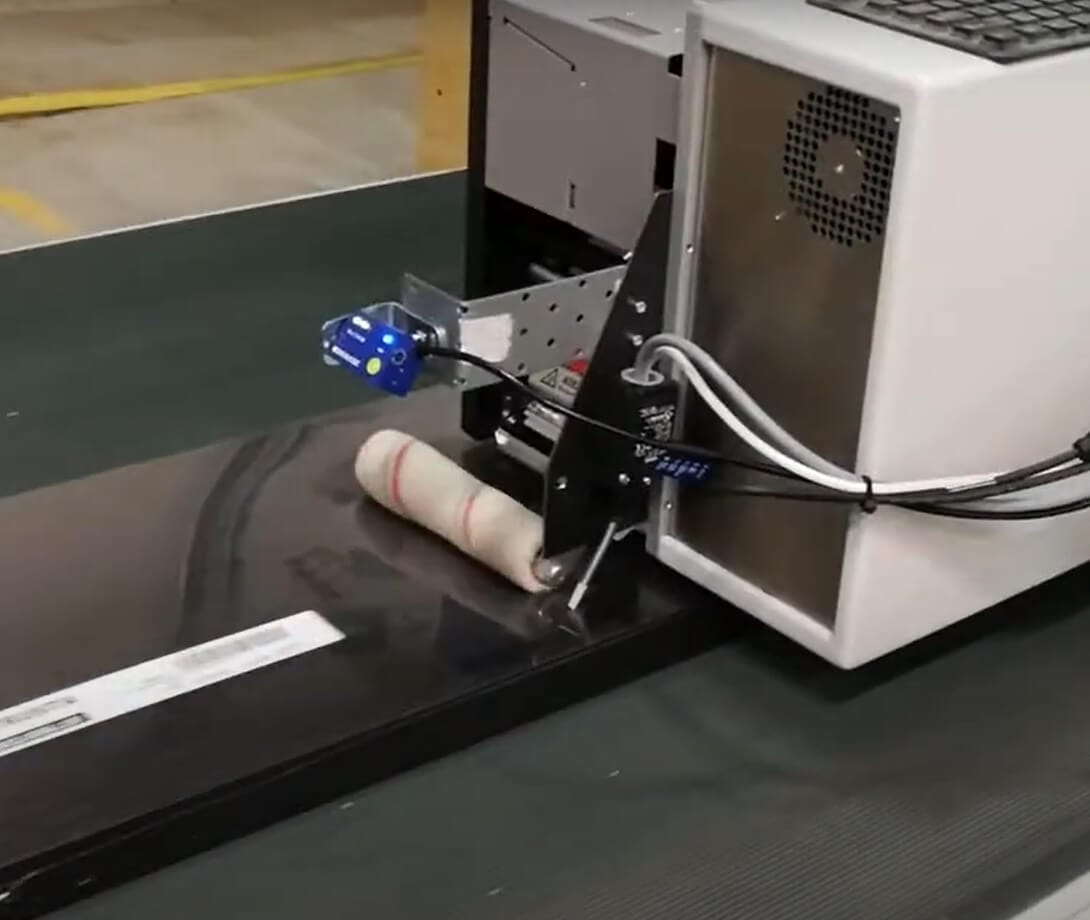

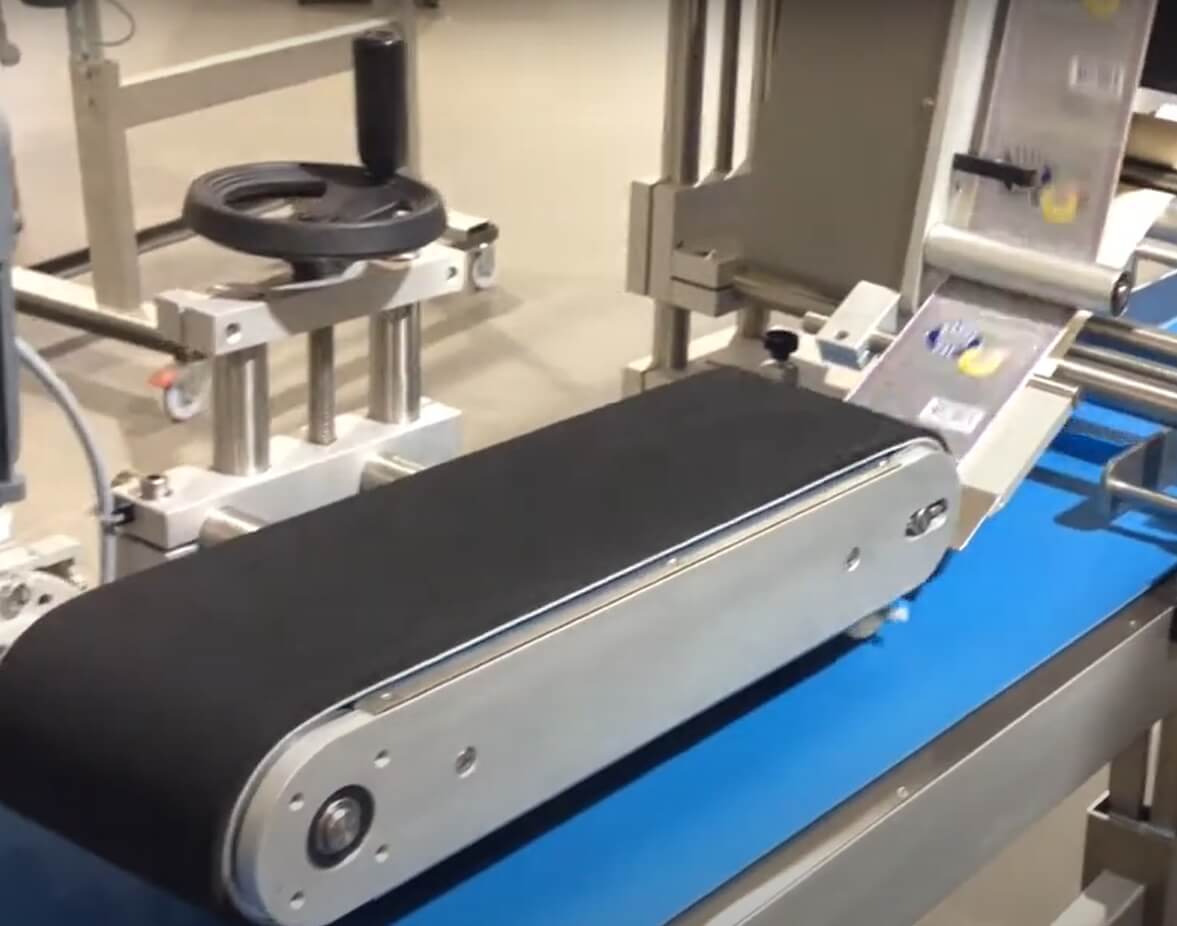

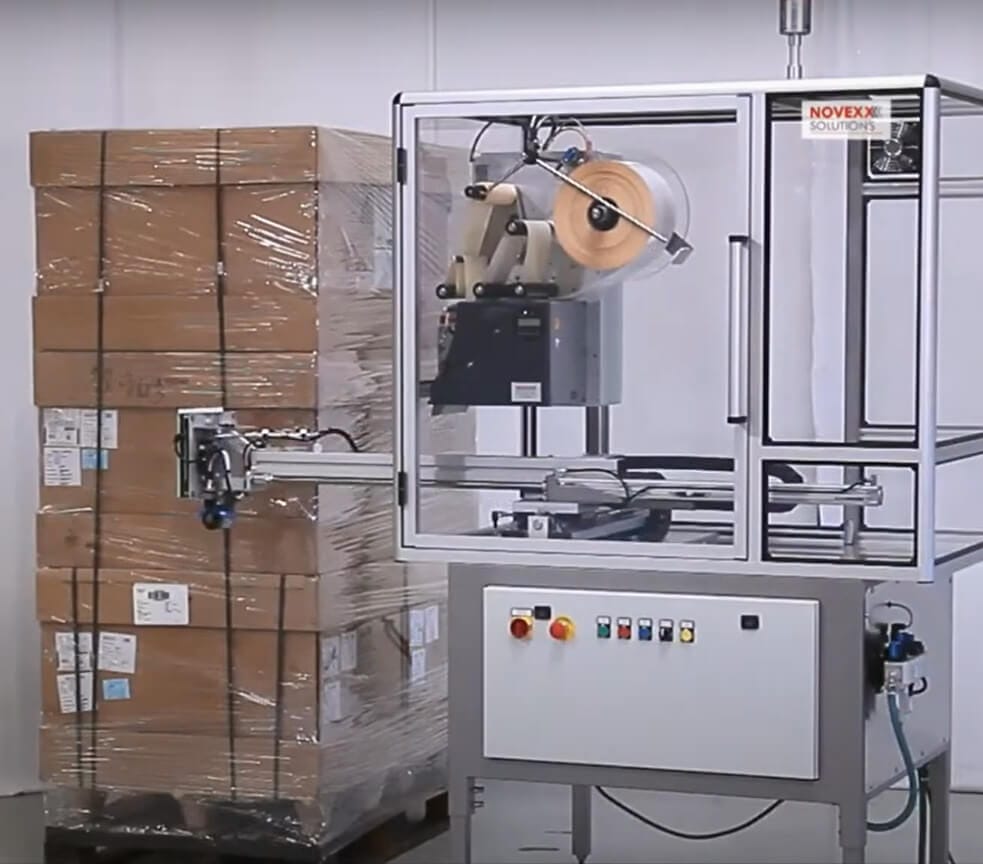

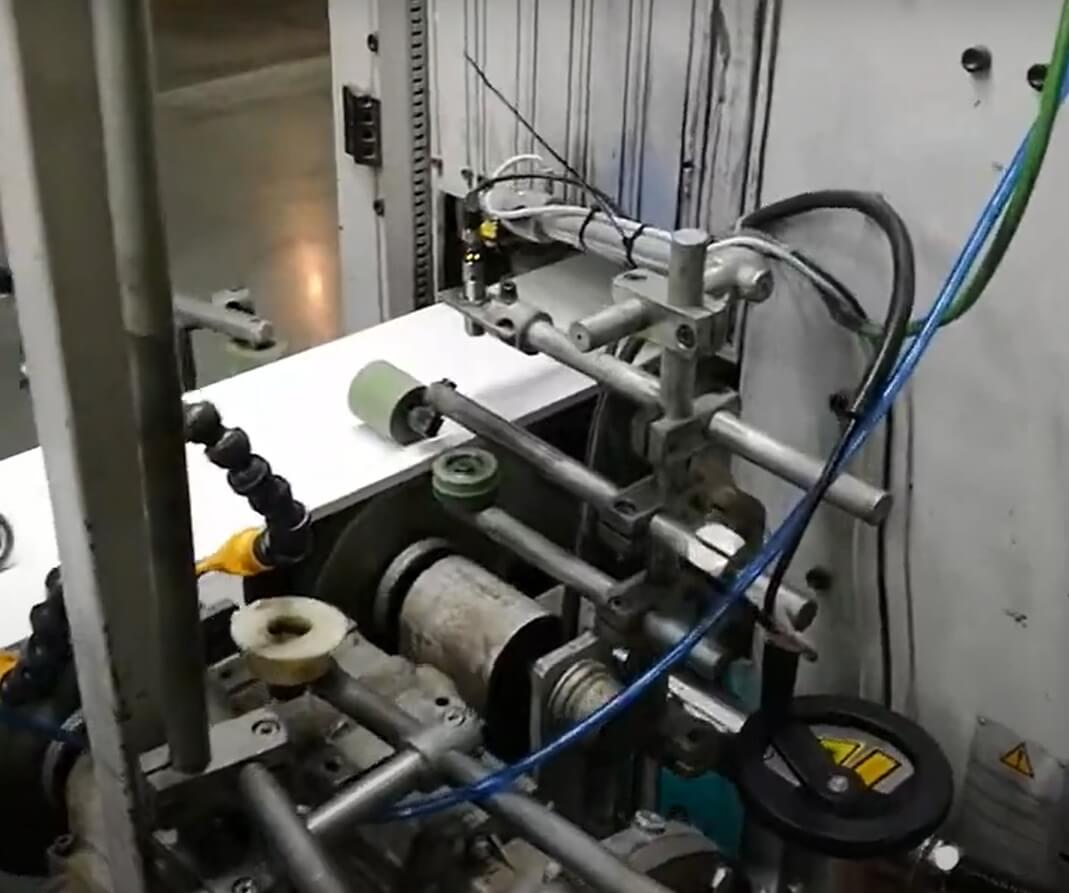

Marking directly on the packaging – a solid, high-quality, good-looking stamp that is part of the packaging. We can offer you printing/marking machines that can easily print variable information, expiry dates, batch numbers, barcodes, etc. on your products. Inkjet, hot stamping, thermal transfer, laser marking – each has its own advantages and disadvantages, ask us and we’ll offer you the most suitable printing method and device for your individual needs.