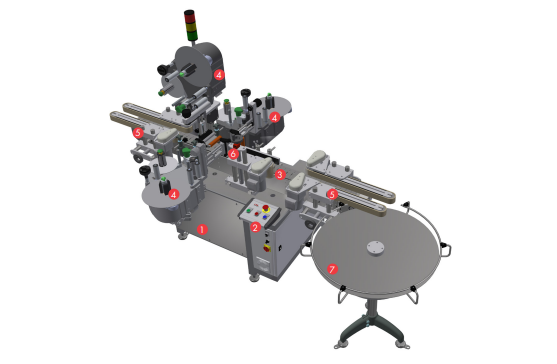

| Device type | Modular label application system (XLA) |

| Marking options | Adhesive labels in various shapes and sizes; multiple labels can be affixed to a single product |

| Gluing positions | Flexible label application at various locations on the product (depending on configuration) |

| Installation in line | Suitable for in-line and stand-alone operation; easy integration into existing lines |

NOVEXX XLA is a configurable, modular label application system designed for industrial product labeling where flexibility and precision are required. Thanks to its modular design, the device can be configured to meet the specific needs of a particular product and line: applying adhesive labels of different shapes and sizes, selecting the direction and position of application on the product.

XLA is particularly useful when a single product requires multiple labels (e.g., decorative and informational) or when labeling must be performed in different locations depending on the type of packaging. The solution is adaptable to various primary products (e.g., boxes, bottles, canisters, containers, etc.) and can be implemented either as an integrated part of the line (in-line) or as a separate work module (stand-alone). In practice, this reduces integration risks, allows for faster adaptation of the system to new products, and ensures more stable marking in intensive production or packaging environments.

If you want, I can make this table more “robust” (e.g., with more specific technical fields), but for that I would need you to tell me which parameters you want to display in your catalog (e.g., speed, label width, roll diameter, accuracy, etc.).