| Device type | Semi-rotary label cutting and finishing machine: DC250 / DC350 |

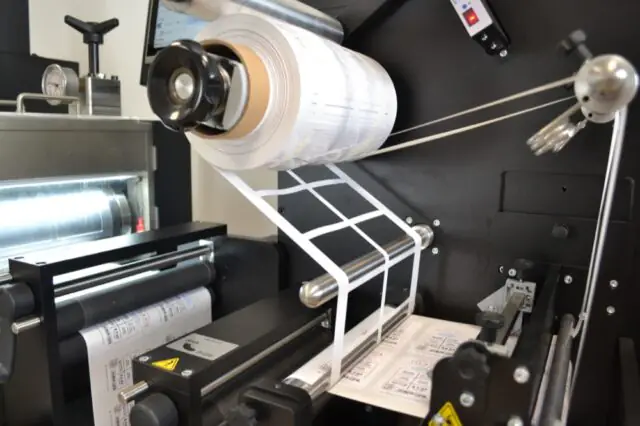

| Finishing processes (in one pass) | Lamination, die cutting, waste matrix removal, slitting, and rewinding |

| Working width class | DC250 – up to ~250 mm; DC350 – up to ~350 mm media (depending on configuration) |

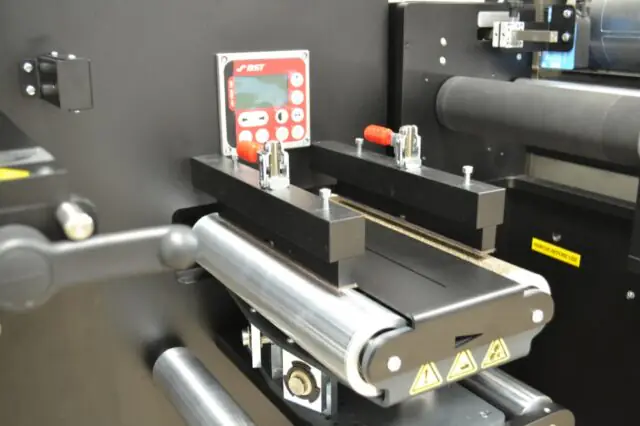

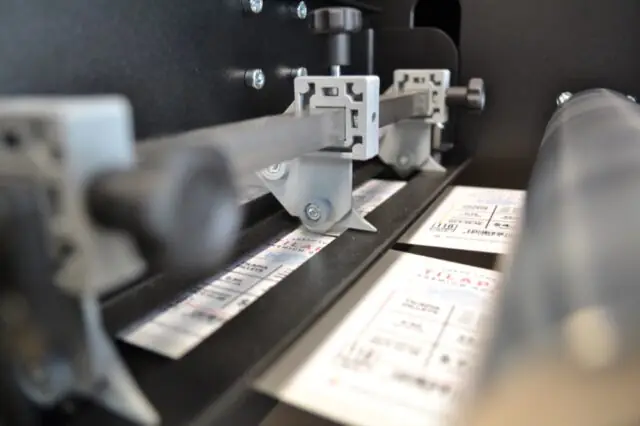

| Cutting tools | Flexible steel dies with magnetic cylinder are used |

Afinia DC250 and DC350 are semi-rotary label cutting and finishing machines designed for short and medium runs where fast finishing, repeatability, and a stable process are important. The system works with pre-printed, continuous label rolls and combines the main finishing steps in a single work sequence: lamination, die cutting, waste matrix removal, slitting, and final rewinding into rolls ready for application.

The practical advantage of these systems is the semi-rotary cutting principle with a magnetic cylinder and flexible steel dies: this allows for efficient repeat orders, maintaining precise contours and reducing unit costs when label shapes are repeated. The DC250 is typically chosen for narrower formats (up to ~250 mm), while the DC350 is chosen for wider jobs (up to ~350 mm), so the solution can be tailored to the width of the printing equipment, label sizes, and planned load.