- Label – paper, synthetic, textile, metallic or other piece of material placed on a product which contains printed information about the product.

- In some cases, adhesive labels are obligatory to the product, in other – they just simplify the work routine in your company resulting in increased effectiveness of human resources, fast data collection and storage, etc.

- We adapt the particular label format to each customer’s work routines, we can offer You various color labels: white, with background, several colors, fluorescent, with imprint (barcodes, logos, brands, etc.), metalized face material, with RFID chips.

Things that should be taken into account when choosinig particular label:

- Required label and label roll formats:

- Physical shape of a label (rectangular, oval, spec. shape);

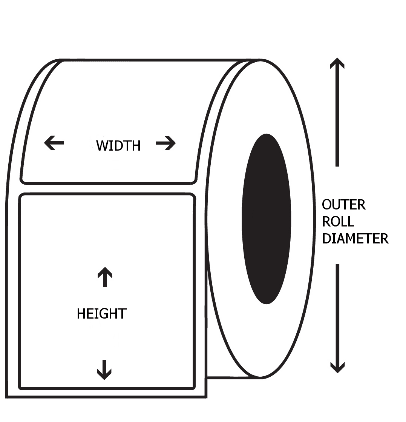

- Dimmensions of a label (width x height, in tables first number always mean widht, second – height with regard to roll winding direction, see ilustration;

- Label orientation on liner ribbon, winding direction;

- Inner core diameter (dependant on used printer);

- Outer label roll diameter (dependant on user printer);

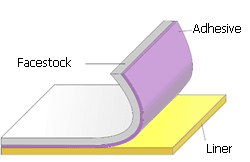

- Label material, see illustration

- Facestock

- Adhesives

- Liner

Vellum – the most popular facestock used for manufacturing adhesive labels. Uncoated matt universal purpose paper. The surface of this paper is silimar to standard office paper surface. Vellum labels are printed with thermal transfer ribbons. It is an economical material for information, logistic and other general purpose labels.

Thermal Eco - paper coated with special heat sensitive coating, which darkens when heated so thermal transfer ribbon is not needed, printing procedure is more simple than thermal transfer. This printing method is called direct thermal. Labels made from this material lose their properties if exposed to UV rays, high temperature of mechanical impact due to this, they are normally used for short-term applications. Price category is similar to Vellum labels printed with thermal transfer ribbon. Main advantage of using this material is very simple work routine and possibility to use labels in mobile/compact printers.

Thermal Top – the same as Thermal Eco, this paper is also coated with special heat sensitive coating plus an additional protective coating, what makes labels made from this material more durable to ambient impacts in comparison to Thermal Eco. Labels made from this material are long-term, ideally fits into mobile printers and can be used even in warehouse. Price category is higher than Vellum with thermal transfer ribbon. Main advantage – very simple work routine and possibility to use labels in mobile/compact printers.

Polypropylene film (PP) – labels made from this material are suitable for applications where higher resistance to mechanical, humidity or chemical impact is required. Film is rigid, do not crack, water resistant. Imprint is long lasting. Film can be solid color, transparent, glossy, matt. PP is the most economical material from synthetic range.

Polyethylene film (PE) – labels made from PE has similar characteristics as PP labels, the main difference between those is that PE is softer and more elastic film what makes it suitable to use on moving surfaces such as shampoo bottles, etc. Film can be solid color, transparent, glossy, matt. PE price category is higher than PP.

Cardboard – non adhesive matt/semi matt relatively thick and hard (~200 gsm) paper. It can be printed with thermal transfer printers or flexographic press. This material is suitable for hanging labels, tickets, informational flyers.

Synthetic paper - non adhesive synthetic paper made of polyprophylene (PP), polyethylene (PE) or polyoefin. It can be printed with thermal transfer printers or flexographic press. Synthetic paper is more resistant to mechanical, temperature or chemical impacts. This material is suitable for hanging labels, tickets, informational flyers.

Supplies for ink-jet printers – HQ ink-jet printers require special coated supplies due to required short ink drying time on the surface. We can offer you analogue materials to ones stated above with a special coating specialy designed for HQ ink-jet label printers.

Standard permanent – most popular adhesive for general purpose labels. Suitable for most of the surfaces, labels can be used in temperature ranges from -20 oC to 80 oC, however, label should only be applied in positive temperatures. In most of the cases the label breaks once trying to remove it and leaves glue residue on the surface. This adhesive price category is lowest.

Removable – labels with this adhesive can be easily removed from the surface without any residual effect on the product. This adhesive is ideal for temporary labelling or in cases marking is needed to be done directly on a finished product, for example glass or crockery.

Strong adhesives – strong adhesive elastic glue, used when extreme and durable bonds are needed. It is hard to remove such label from the surface without cracking the label, significant glue residue stays on the surface after removal.

Deep-freeze – adhesive specially designed for low temperature applications on frozen products. Although the these labels can be applied in negative temperature, please take in mind that the surface should be clean and dry, the label will not stay in its place if applied to white frost.

Special – if Your work routine requires specialty adhesives different than the ones stated above, please contact us and we will offer you the optimal solution for Your needs. The main adhesive characteristics are: initial tact, nominal adhesion, application and service temperatures. Let’s say there are adhesives that have low initial tack but after few hours after application the glue migrates to the surface resulting in strong bonds.

Technological silicone or wax coated paper specially designed to be used as a transport layer of adhesive labels – labels are delivered wound up in a roll, where the labels are placed on a liner ribbon. Due to silicone layer, labels can be easily removed from the liner. Standard liners are one side coated. Most common colors of the liner are yellow and white. The color of the liner does not have any influence the label itself, however, it has a small impact to the label stop sensors in printing equipment so in practice there are few different colors.